Robotic Fabrication Lab

Automation in construction is becoming increasingly important to improve the productivity of the sector, which has been stagnant for decades. With the development of numerous AM technologies for construction, this technology is now a viable automated option to replace traditional methods that are mainly done by manual labor. But while some AM tools are ready for use, there are still no conveniently deployable software solutions that can be used to integrate AM methods into the usual design process.

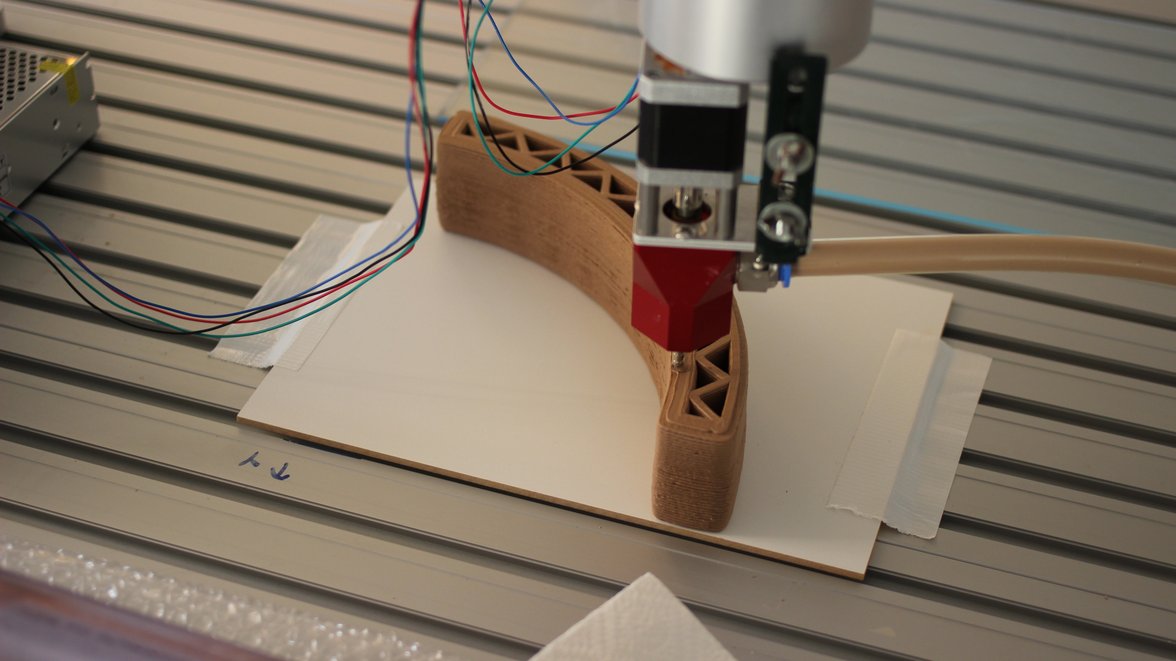

The Robotic Fabrication Labs is equipped with two advanced UR robotic arms and with an extrusion system for 3D printing in model size with clay. In addition, advanced sensor systems are available that can be linked to the AM process for detailed capturing of the printed component.

The Robotic Fabrication Lab offers a comprehensive research platform, with which the Chair of Computational Modeling and Simulation (Prof. Dr.-Ing. André Borrmann) is developing new methods for the integration of AM into the construction planning and for the complete automation of the AM process and its quality control.