Motivation

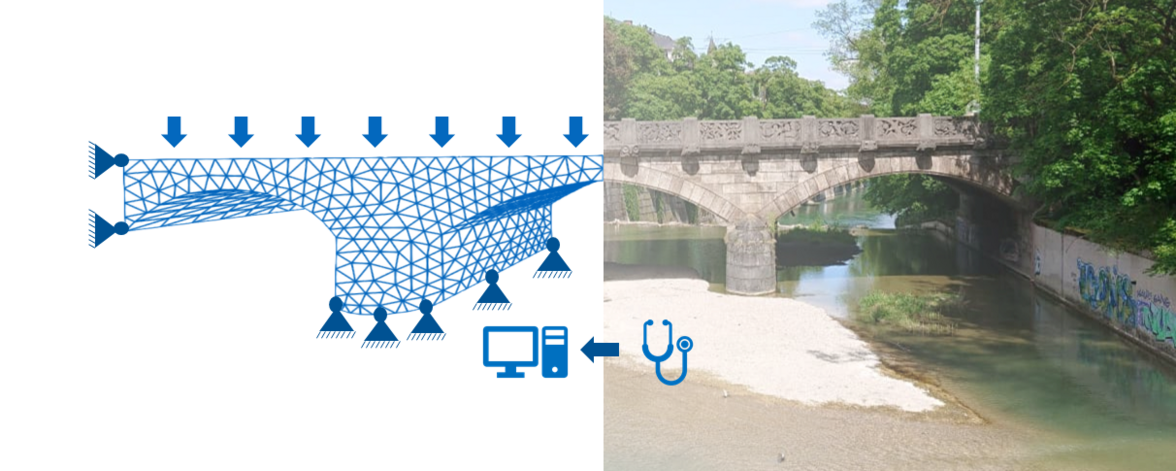

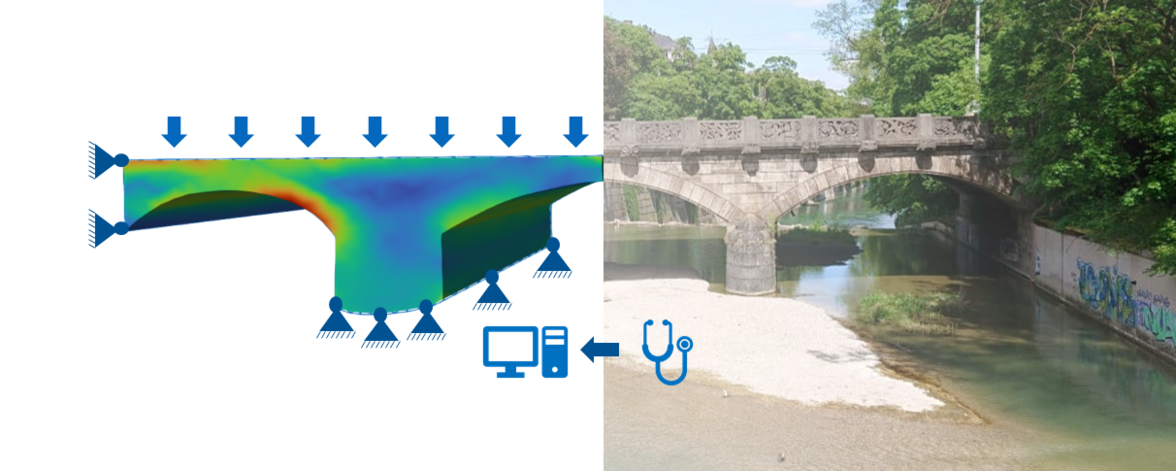

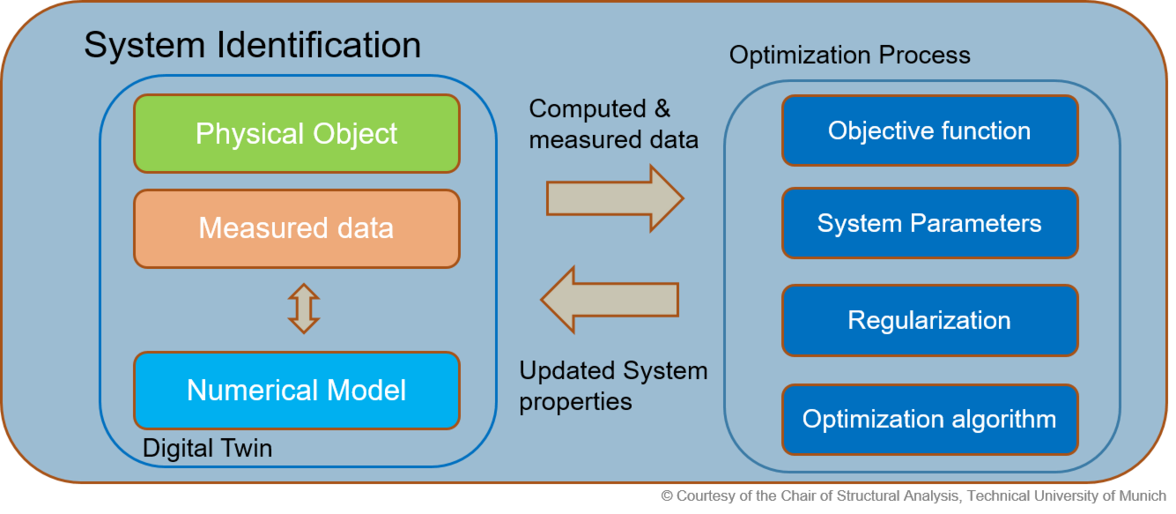

During their lifecycle, structures age and change their properties due to different reasons, for instance damage, corrosion or fatigue. With increasing maturity of sensor technology and numerical simulation techniques, it is possible to build digital representations (Digital-Twining) of complex structures. One of the most important steps of Digital Twinning is system identification, which involves identification of the current state of the material properties and/or localization of the weakening. This requires solving the inverse problem using suitable parameterization of the structure which is typically formulated as an optimization problem.

Research Collaborators

External Collaborators

- Prof. Rainald Löhner, Center for Computational Fluid Dynamics, George Mason University, USA

- Prof. Harbir Antil, Center for Mathematics and Artificial Intelligence, George Mason University, USA (Digital Twin Lab)

- Dr.-Ing. Ihar Antonau, Technical University of Braunschweig, Germany

- Dr.-Ing. Christian Flack, Technical University of Braunschweig, Germany

- Jan-Malte Wessels, Technical University of Braunschweig, Germany

Industrial Collaborators

- Stefan Boschert, Siemens AG

- Christoph Heinrich, Siemens AG

Project

Adjoint-Based System Identification of Large-Scale Structures (TUM-IAS Hans Fischer Senior Fellowship funded by Siemens AG)

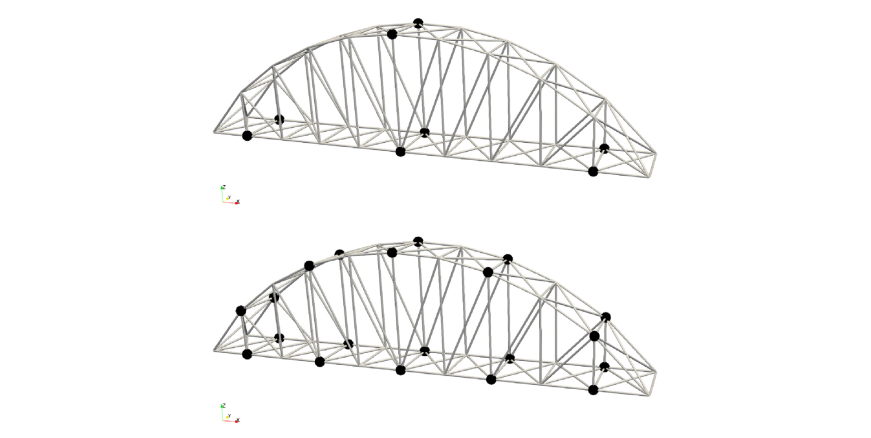

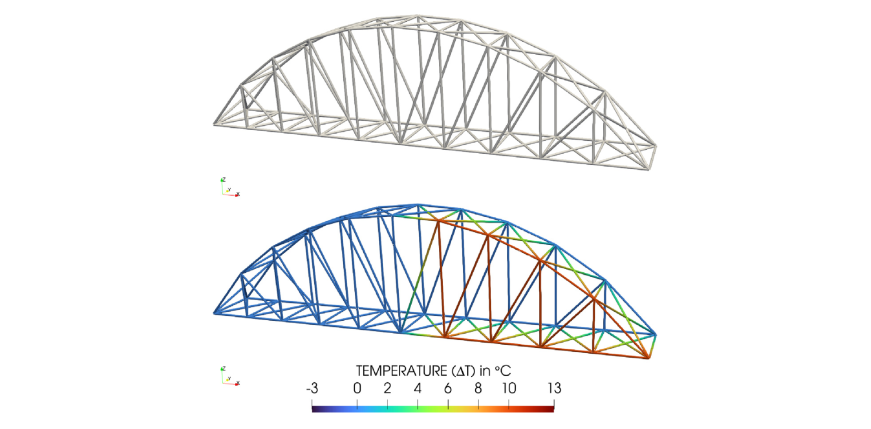

Adjoint-Based Recovery of Thermal Fields From Displacement or Strain Measurements

A finite-element method dependent adjoint-based procedure to determine the temperature field of structures based on measured displacements/strains and a set of standard loads is developed and tested. Given a series of force and deformation measurements, the temperature field is obtained by minimizing the adequately weighted differences between the measured and computed values. Results show that the proposed approach can accurately reconstruct the target thermal distribution, especially when more sensors are used. Additionally, it is observed that the sensors do not need to be positioned in the region of interest; the method remains effective as long as the sensors can detect changes related to that area.

Adjoint-Based Determination of Weaknesses in Structures

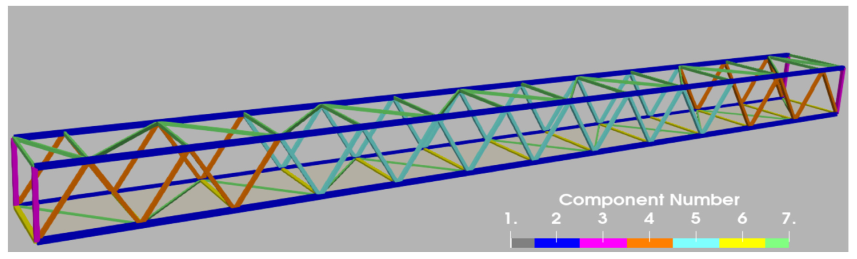

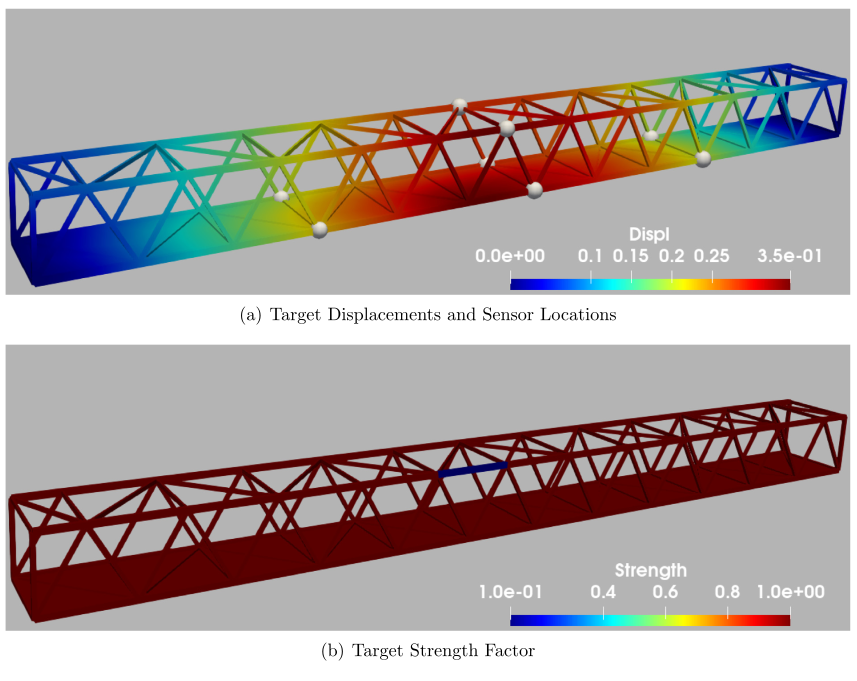

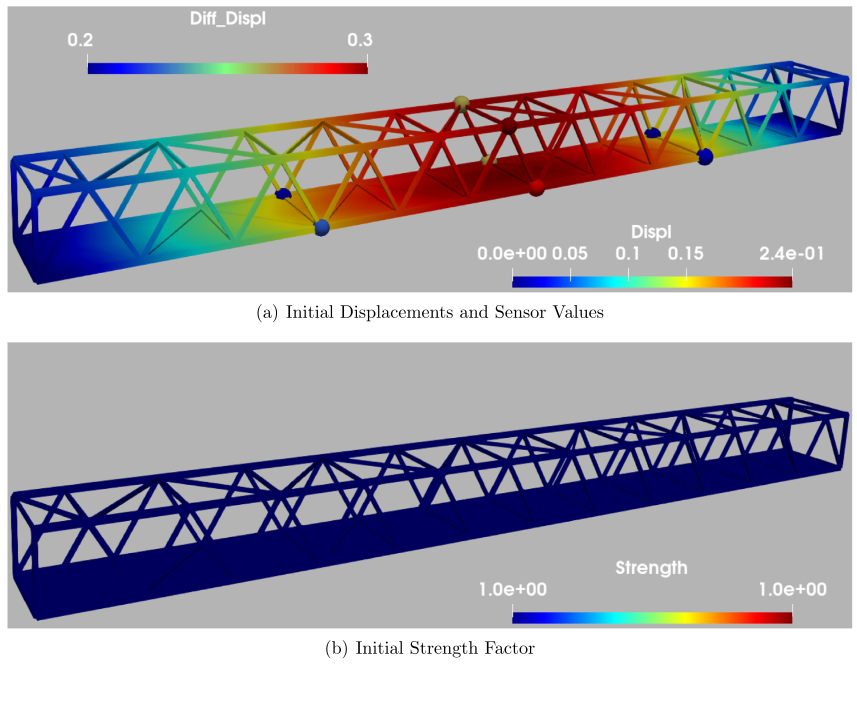

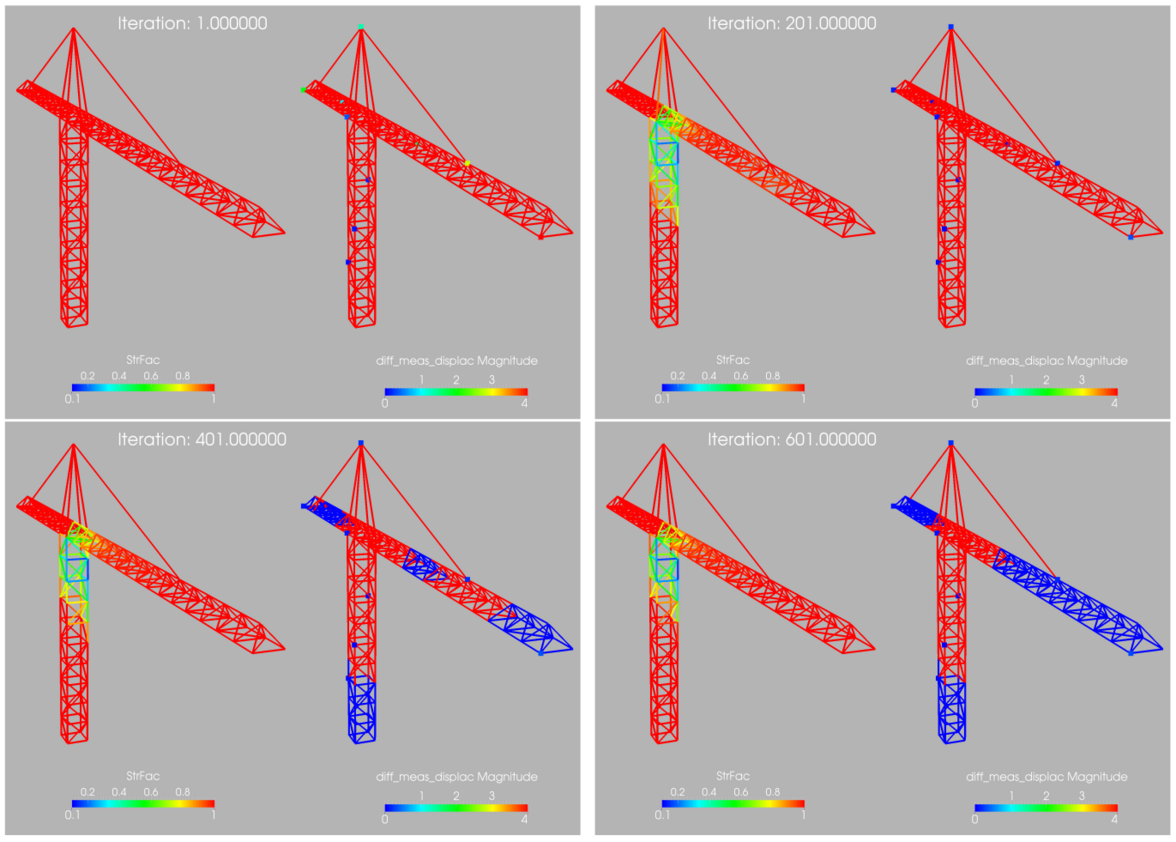

An adjoint-based procedure to determine weaknesses, or, more generally the material properties of structures is developed and tested. Given a series of force and displacement/strain measurements, the material properties are obtained by minimizing the

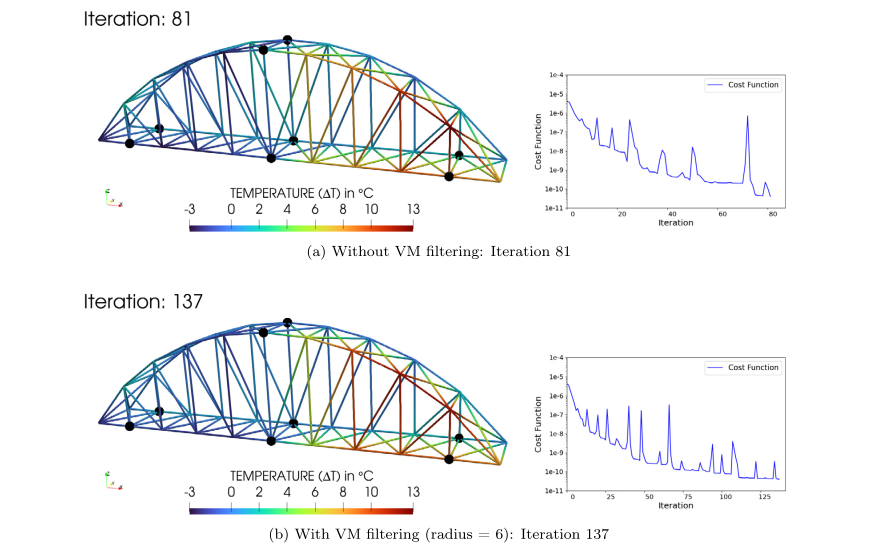

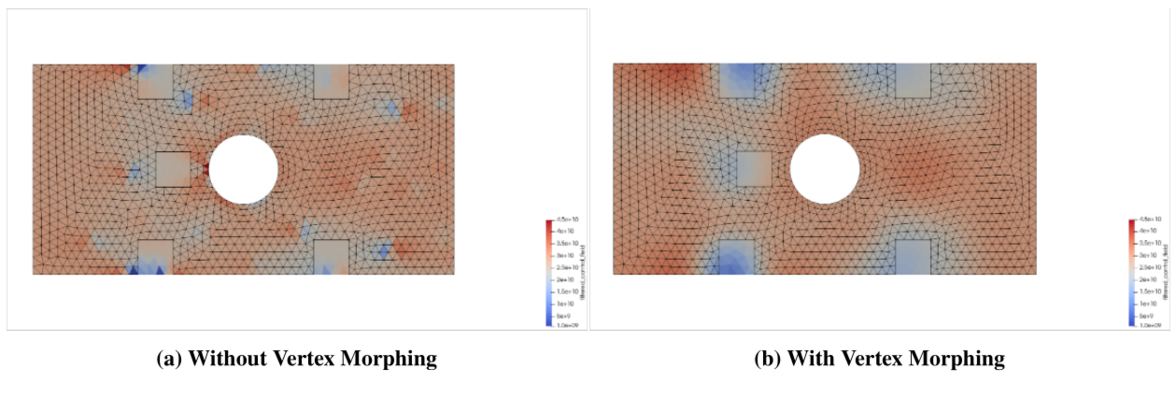

adequately weighted differences between the measured and computed values. The approach is directly based on the finite element model of the structure of interest, which can be arbitrarily complex and be composed of any kind of element formulation. This is especially advantageous in complicated real-world applications. As a consequence, the procedure can provide highly resolved parameter distributions within the structure and allows for the localization of e.g. damage regions or other zones with deviations from the planned configuration. Several examples with truss, plain strain and volume elements show the viability, accuracy and efficiency of the proposed methodology using both displacement and strain measurements. An important finding was that in order to obtain reliable, convergent results the gradient of the cost function has to be smoothed appropriately.

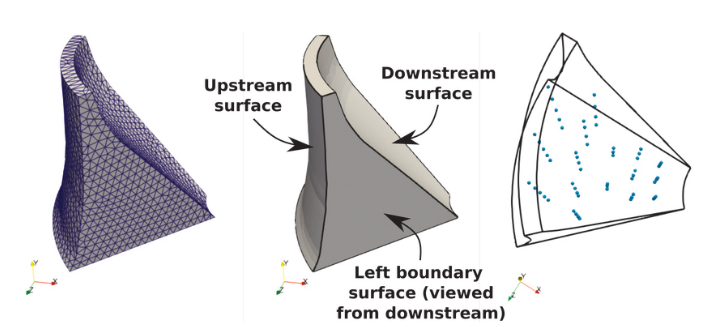

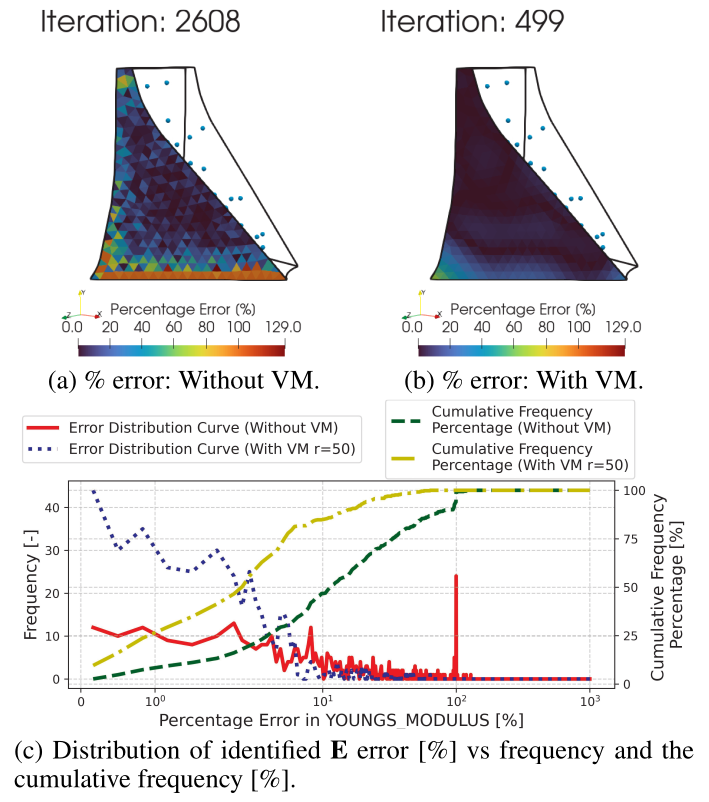

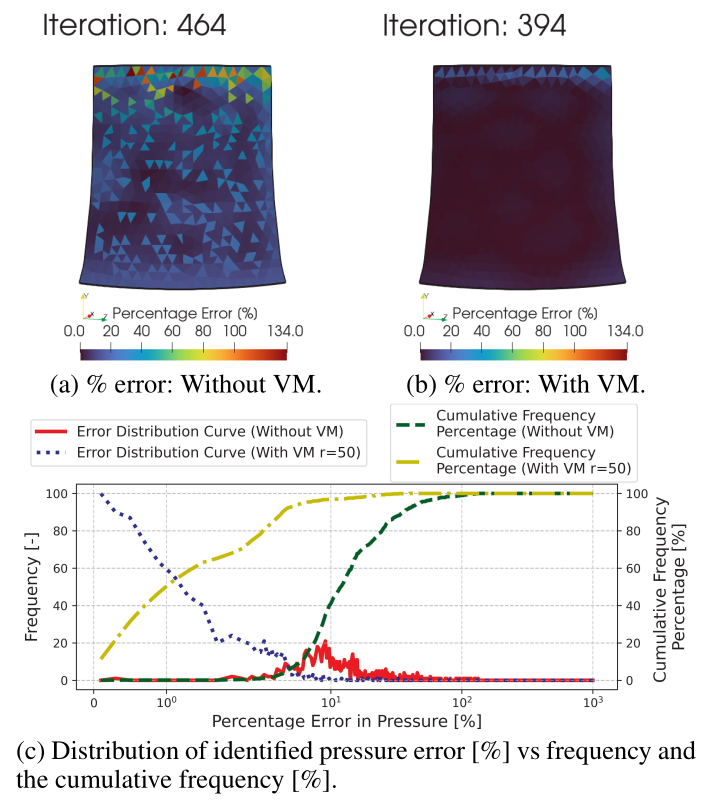

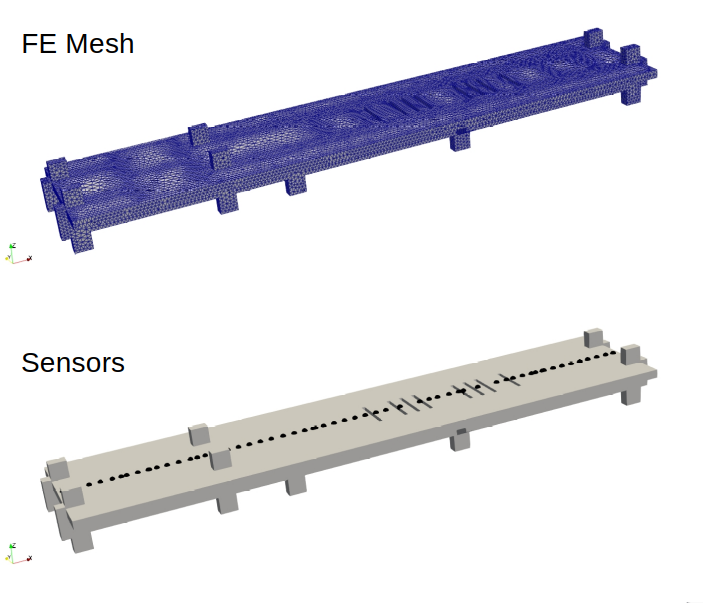

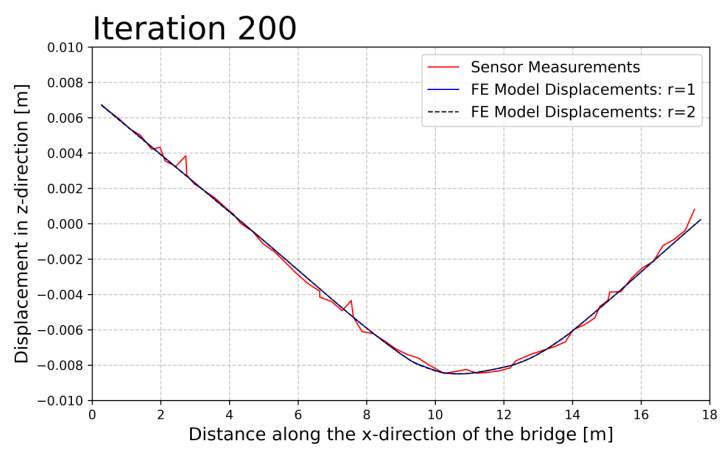

Adjoint-Based System Identification for Model Validation and Qualification

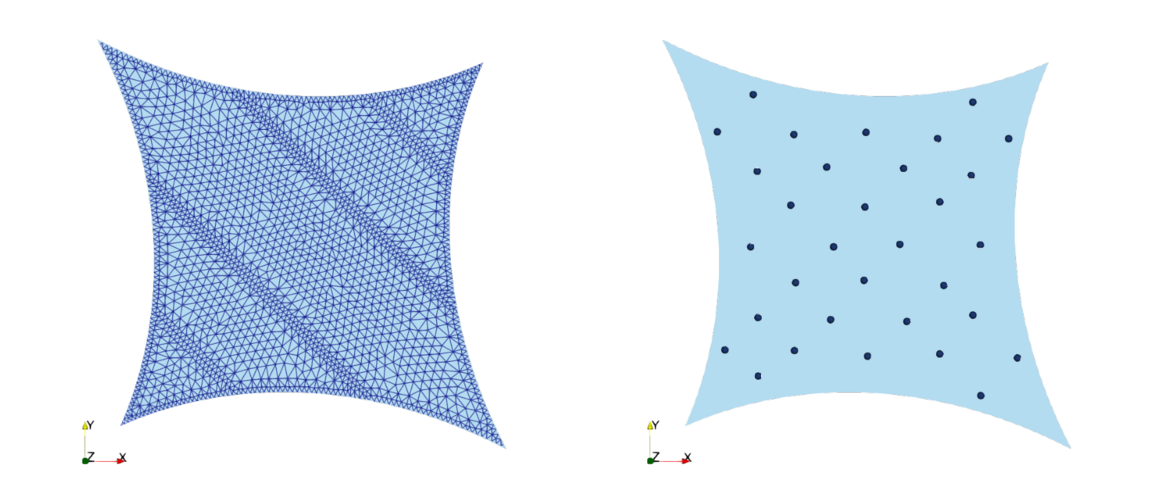

Many structural health monitoring (SHM) techniques use finite-element models to track the health of a structure throughout its lifetime. To have an accurate system identification of the current state, it is vital that the model is accurate in terms of geometry, loading, and boundary conditions, such that it qualifies to conduct SHM and track other relevant damage indicators. Therefore, a finite element (FE) dependent, high--fidelity, adjoint--based, optimization--driven procedure focusing primarily on factors other than the material parameters, i.e., related to boundary and loading conditions is proposed. An optimization problem with the objective of minimizing the weighted differences between the model response and the sensor measurements is formulated. The gradients are efficiently calculated using the adjoint method, and Vertex Morphing (VM) is used to regularize the optimization by filtering the sensitivities. The results demonstrated a sufficiently good identification of the system parameters and capturing underling trends.

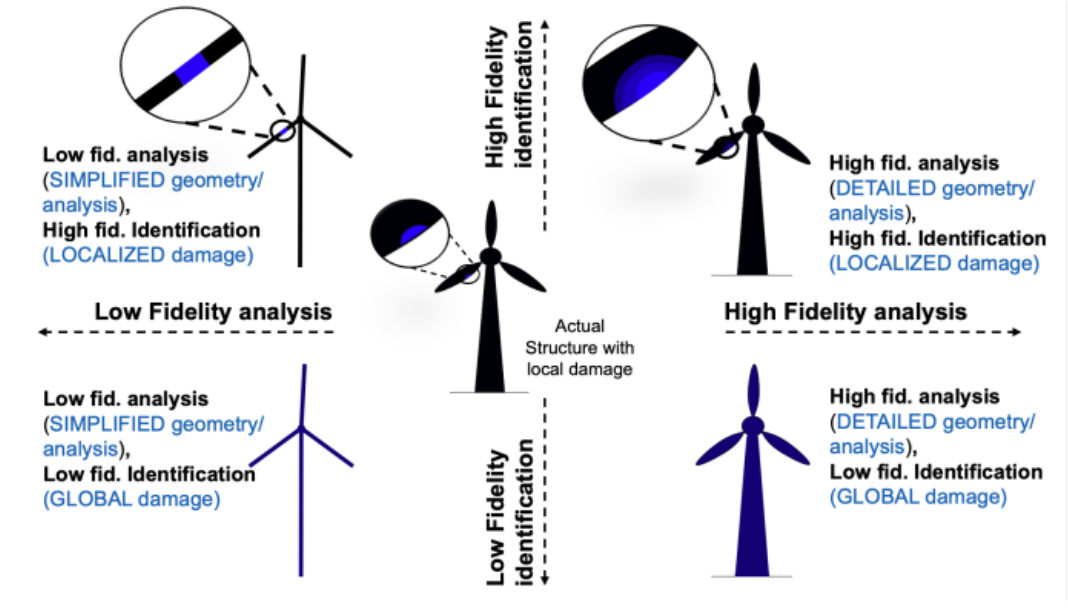

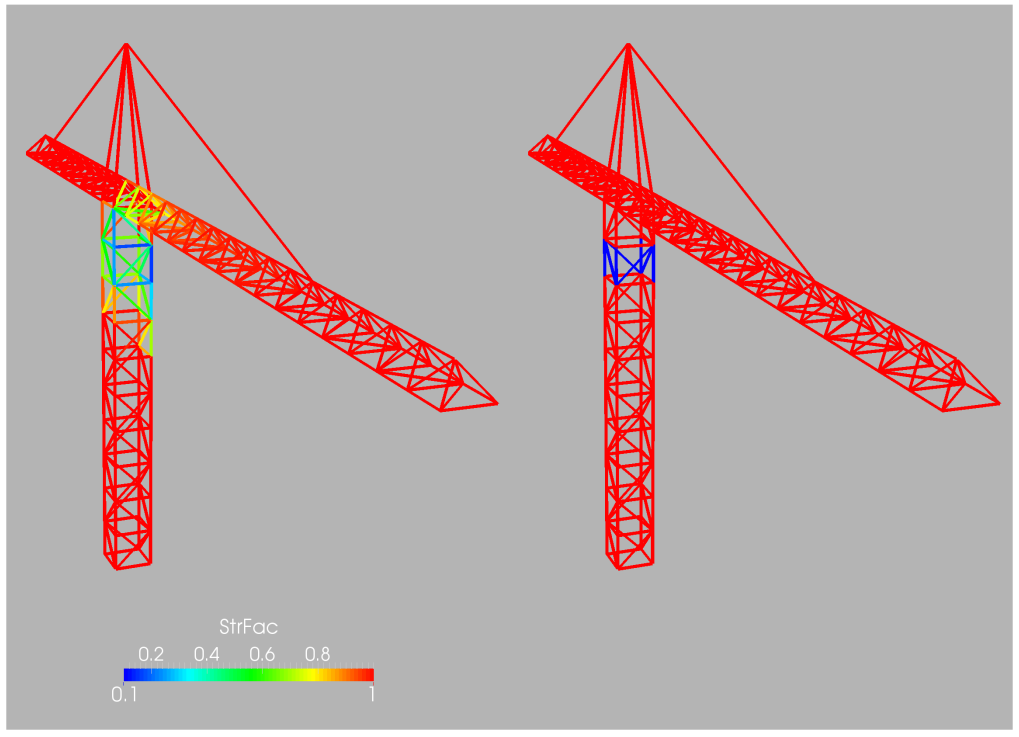

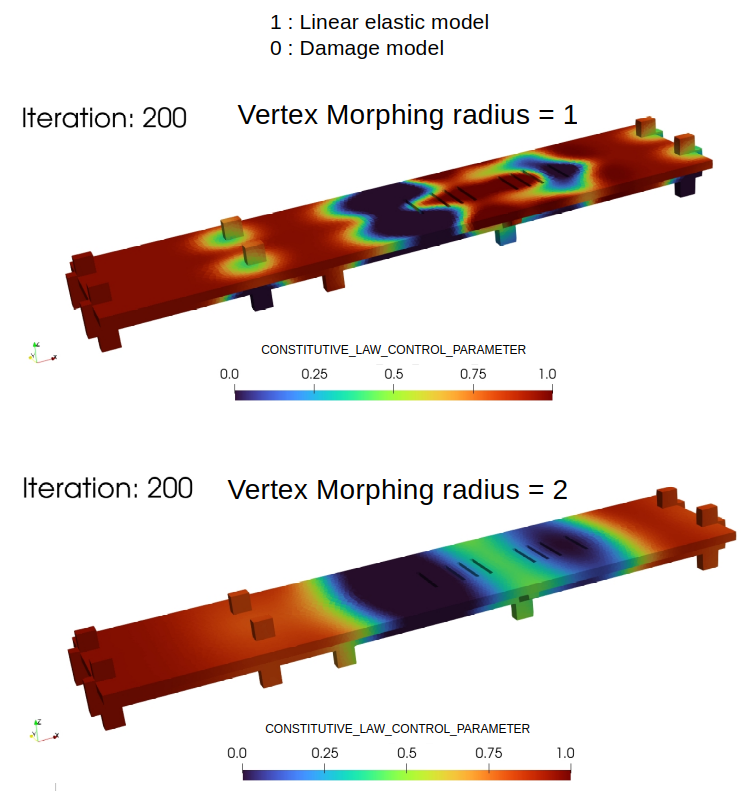

High-Fidelity Digital Twins: Zooming in on Weaknesses in Structures.

An adjoint-based procedure to determine weaknesses, or, more generally, the material properties of structures is improved by implementing two techniques to progressively reduce the regions considered as weakened. In this way, the number of degrees of freedom that are being optimized is reduced, leading to faster convergence and a better definition or `sharpening' of the weakened region. Several examples show the viability, accuracy and efficiency of the proposed methodology and its potential use for high fidelity digital twins.

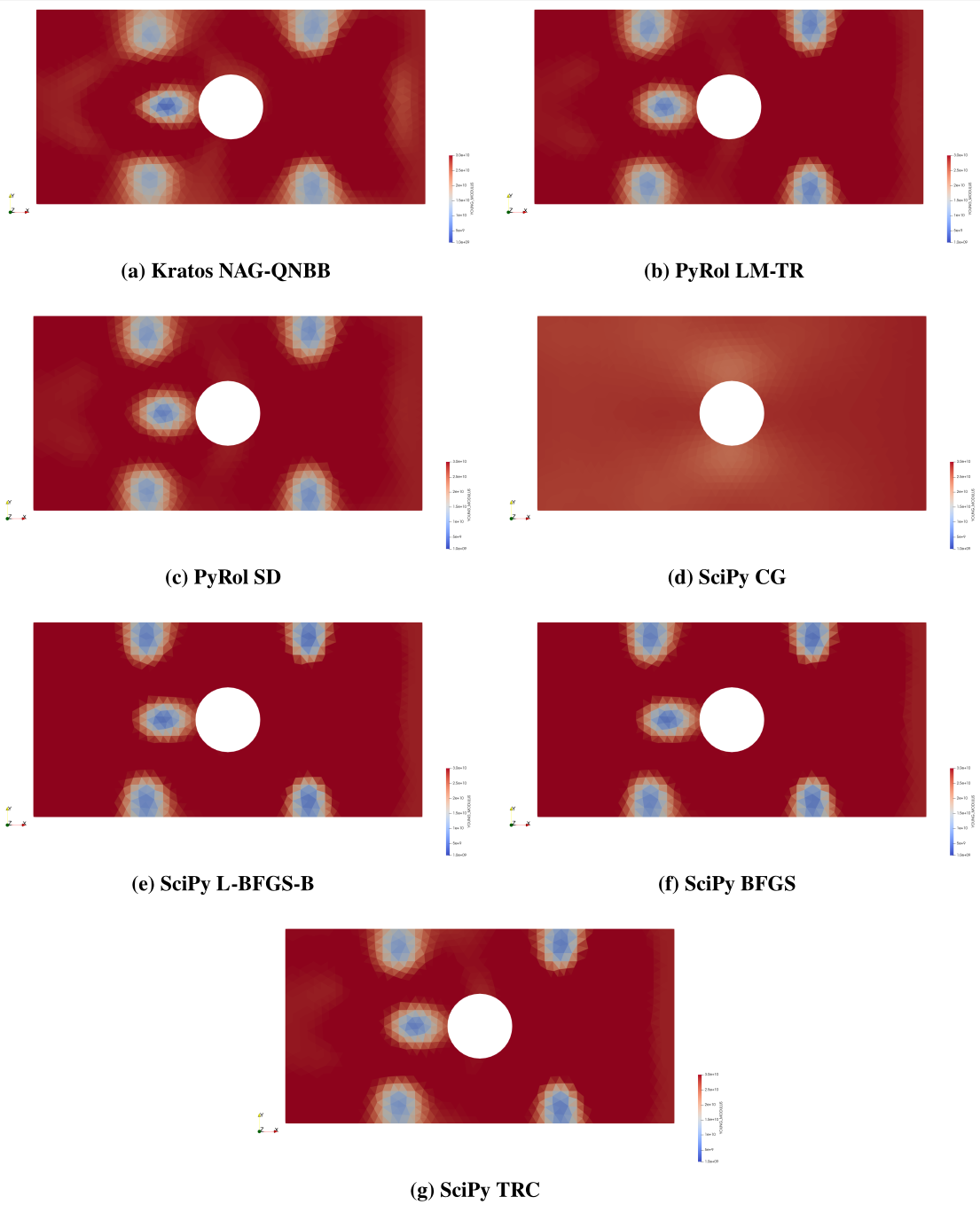

Comparison of the First Order Algorithms to Solve System Identification Problems of High-Fidelity Digital Twins.

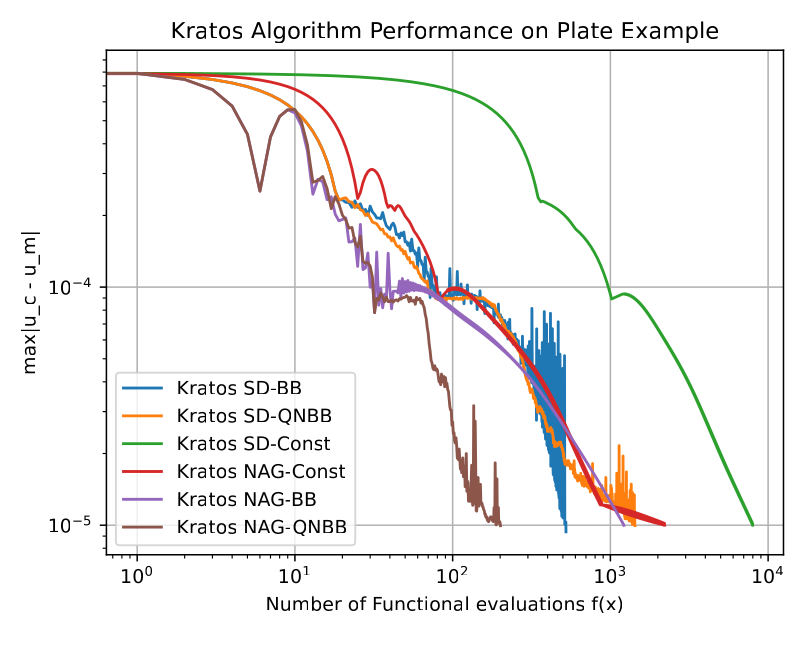

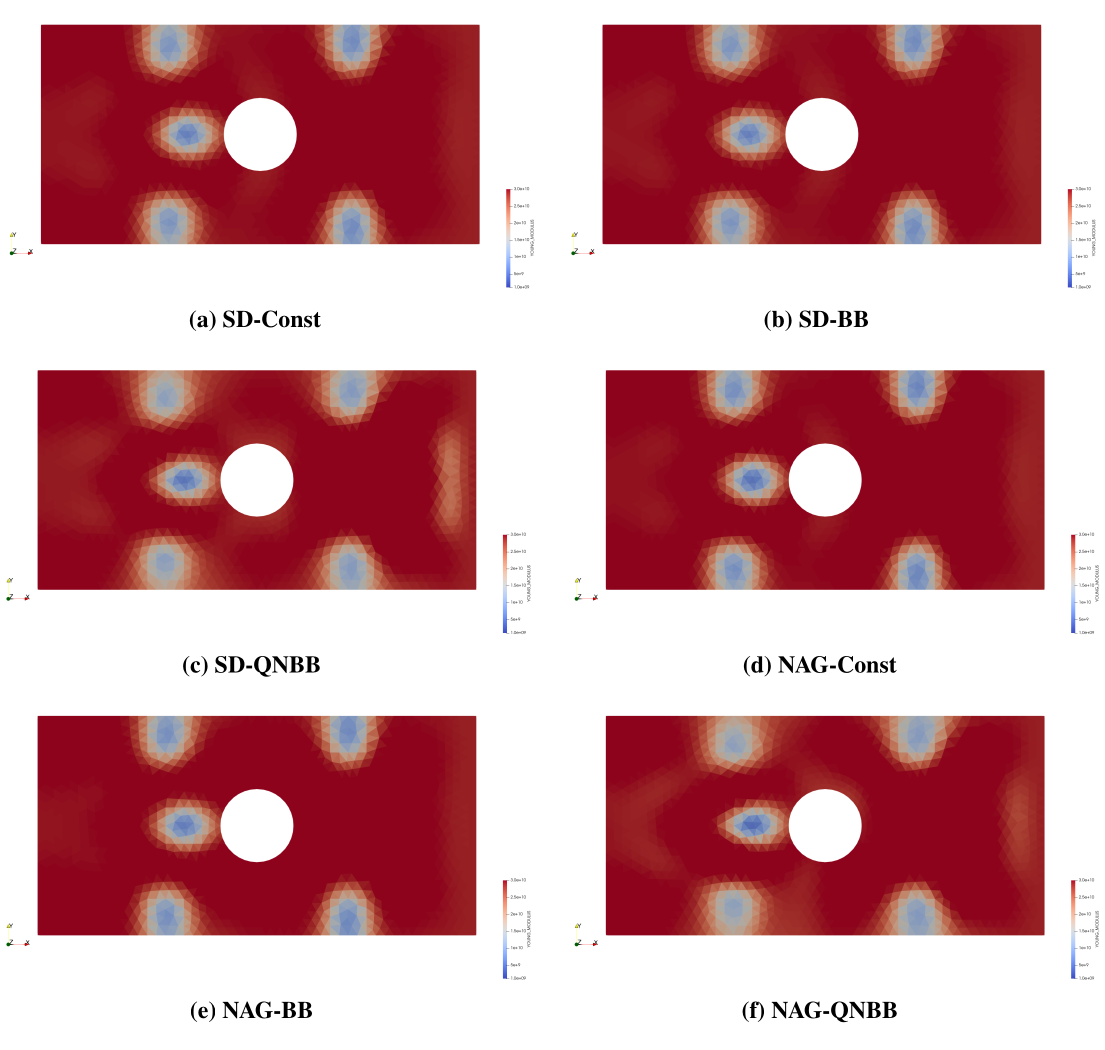

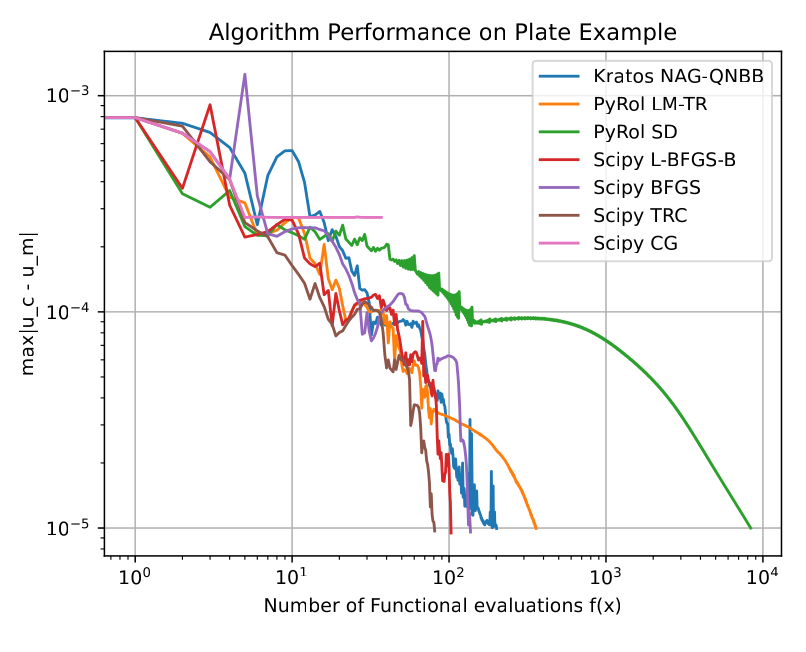

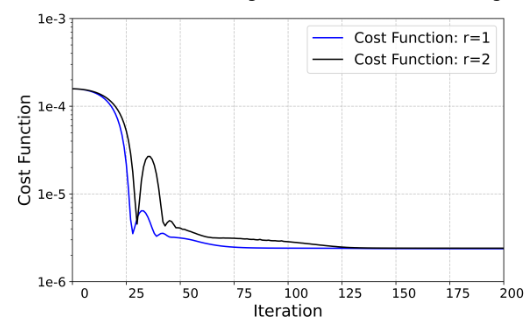

This work focuses on solving the system identification problems of the high-fidelity digital twin based on the measured data via an optimization process. The cost function formulation is based on the aggregated error between measured and computed displacements in different locations. The work aims to test different optimization algorithms with the Vertex Morphing regularization technique. The Nesterov accelerated gradient method is reviewed, studied on a representative structural benchmark, and compared to well-known base methods, such as the steepest descent method. By implementing this advanced methodology, practitioners can achieve timely and accurate assessments of structural integrity, leading to better-informed decision-making regarding maintenance and safety protocols. This research contributes to the ongoing advancement of Digital Twin technology, promoting safer and more efficient infrastructure management.

Antonau, I., Warnakulasuriya, S., Ansari, T., Airaudo, F., Antil, H., Löhner, R., & Wüchner, R. (2025). Formulation and regularization of the optimization problem for adjoint-based digital twin construction. In 16th World Congress on Structural and Multidisciplinary Optimization (WCSMO 2025).

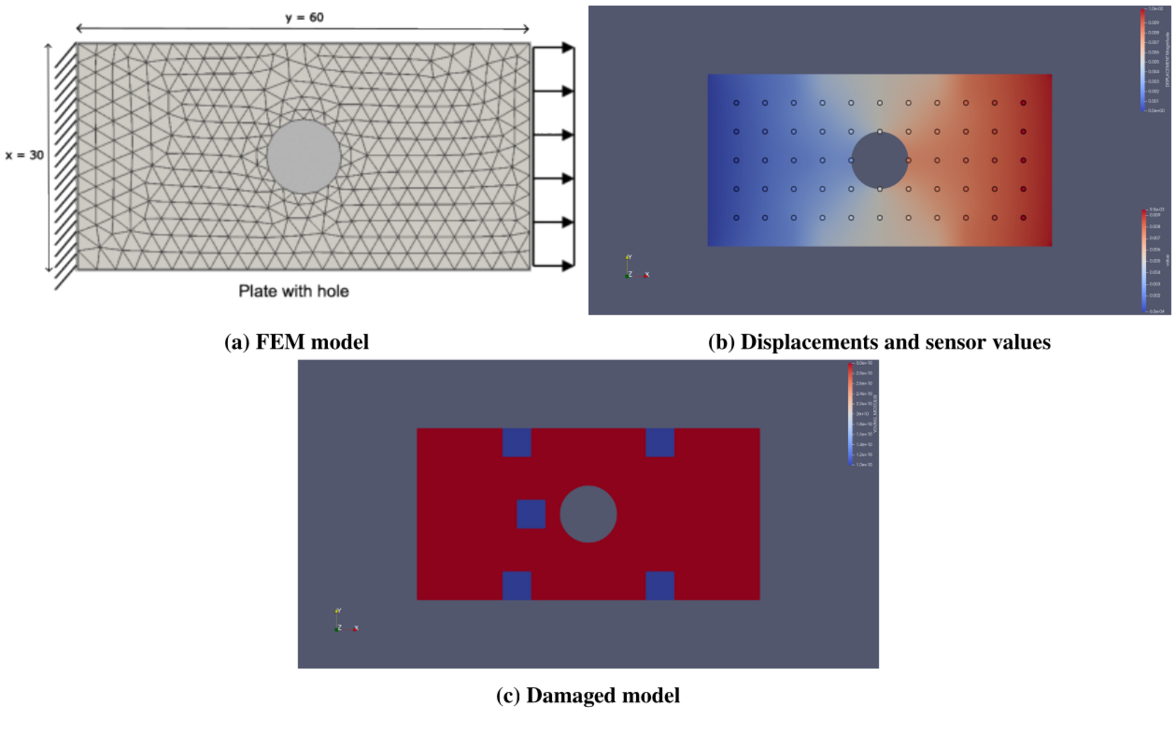

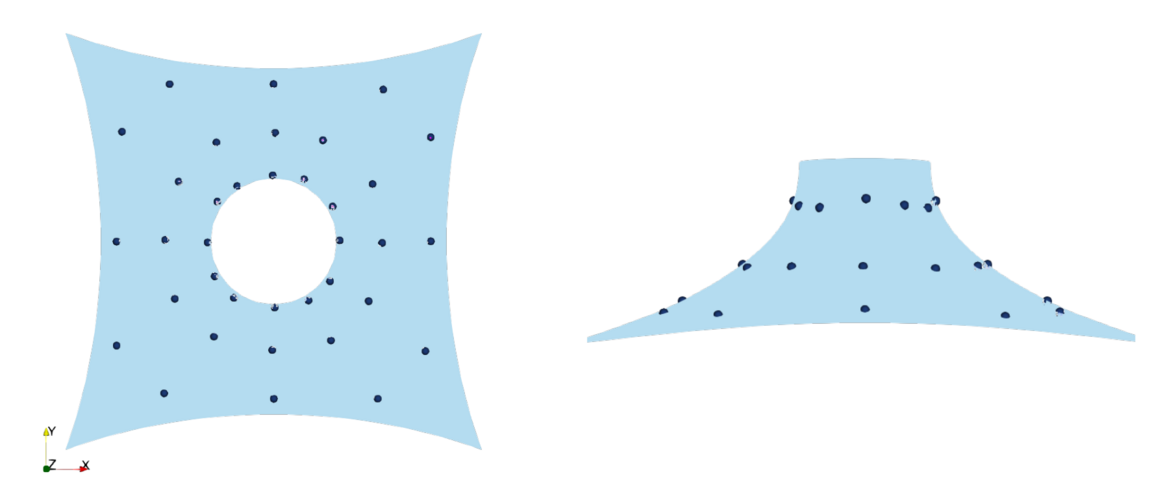

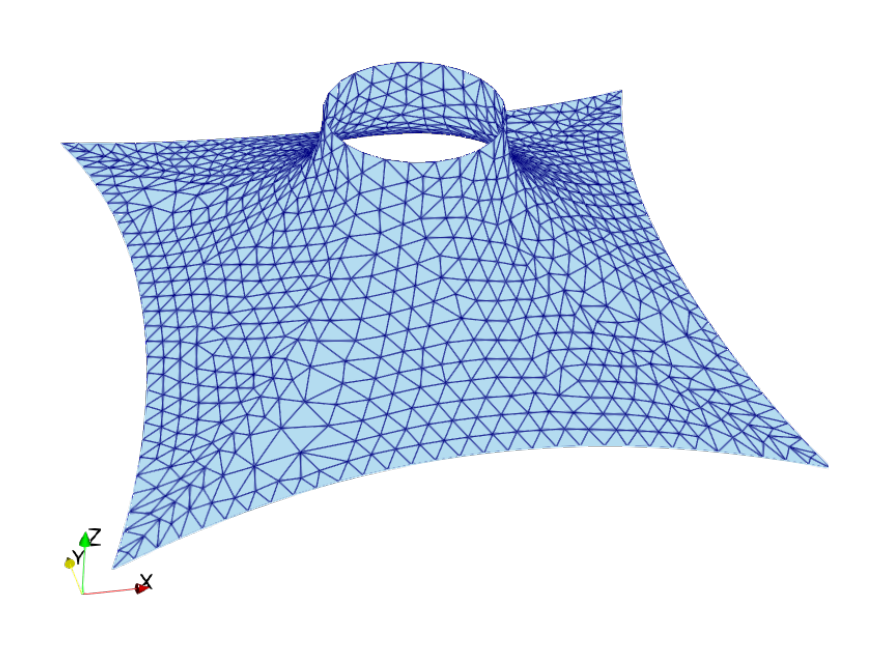

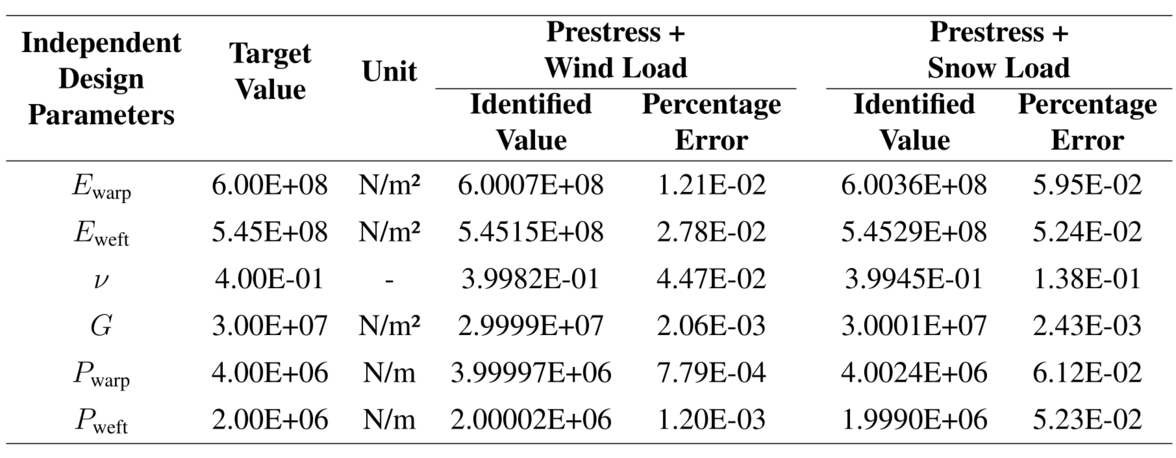

Adjoint-Based Constitutive Parameters Identification in Membrane Structures Using Deformation Measurements

Membrane structures, valued for their flexibility and lightweight nature, are increasingly used in engineering applications. However, their mechanical behavior is challenging to predict due to uncertainties in material properties arising from fabrication methods, environmental exposure, and aging. To address this, we employ an adjoint-based system identification framework that estimates key constitutive parameters and prestress components directly from measurement data. The approach formulates a gradient-based optimization problem, leveraging adjoint sensitivities to efficiently recover material behavior from limited displacement or strain sensor input.

Adjoint-Based Material Parameters and Constitutive Model Identification From Deformation Measurements.

Accurate description of the constitutive relation and the material parameters are necessary for constructing accurate digital twins of structures. However, the real-world structure’s material parameters and constitutive relation might differ from the ideal properties used in the model. Common SHM approaches focus on identifying the material parameters such as Young’s modulus of the structure to detect an anomaly. While this information represents the current state of the structure accurately, prediction regarding the remaining life of the structure is challenging as the underlying constitutive behaviour has likely changed, thereby highlighting the necessity of material model-accurate predictive digital twins. In this work, we address the material model identification by first decoupling it into two manageable sub-problems, material parameters identification and constitutive model identification, to gain a deeper understanding of each component’s characteristics. The parameter identification includes identifying the material constants, given a constitutive law. While the constitutive problem discovers the constitutive model influencing the material behaviour given a set of material parameters. Both the sub-problems are formulated as adjoint-based sensitivities driven optimization tasks with the objective to minimize the weighted differences between the model and the deformation measurements obtained from displacement or strain sensors.