Overview

Ongoing research projects:

- AiF FOSTA 22501 N/1 - Structures in steel-wood mixed construction that are safe from a fire protection point of view

- AiF-FOSTA 21403 N - Load-bearing behavior of shear studs in composite floor decks with high ribs under fire loads

Completed research projects:

- AiF GAV FOSTA DASt 21536 N Fire resistance of hot-dip galvanized composite beams made of high and high-strength structural steels

- AIF FOSTA P 1139 - Temperaturentwicklung in Hohlräumen abgehängter Decken sowie in Hohl- und Doppelböden und deren Auswirkungen auf das Tragverhalten innenliegender Stahlkonstruktionen - „Brand im Hohlraum“

- GAV AIF IGF 18887 N - Feuerwiderstand von feuerverzinkten, tragenden Stahlkonstruktionen im Brandfall

- AIF FOSTA P 1162 - Mindestverdübelung von Verbundträgern bei Brand

- AIF IGF 16242 N - Nutzung der Membranwirkung von Verbundträger-Decken-Systemen im Brandfall

- AIF IGF 17220 N - Optimierter Einsatz intumeszierender Anstriche im Stahlbau

Fire safety of hybrid steel-timber construction systems

- AiF-FOSTA-Project: IGF-Nummer 22501 N/1

- Timeline: 2022-2025

- Cooperations: Technical University of Munich, Chair of Timber Structures and Building Construction

The steel-wood mixed construction method offers the combination of many positive building material properties. In the case of steel, these include the excellent recycling possibilities as well as the pronounced strengths and resulting spans, and in the case of the natural-based material wood, the storage and avoidance of CO2. This opens up enormous potential, especially in multi-story construction for changeable and flexible residential use as well as for office, administrative and commercial use. In fact, however, there are no validated verification procedures for the steel-wood mixed construction method that allow a regulated assessment of the fire resistance and fire protection safety of this construction method. The aim of the research project is therefore to close these gaps in knowledge by providing appropriate design approaches and construction details.

On the one hand, this is to be done by quantifying the protective effect of laminar timber components and timber cladding for steel profiles in the event of fire, as well as the resulting load-bearing capacity. In addition, constructive solutions are to be worked out which enable a protective effect of the wooden components without premature falling away, exclude uncontrollable fires in the component joints between steel and wood and enable simple refurbishment. Ultimately, basic principles and material parameters are to be generated that allow performance-related verification under natural fire exposure for steel-wood mixed structures.

The research results will be used to further develop a construction method that can be used to flexibly meet current and future architectural needs and resource-saving design specifications, while at the same time being easy to deconstruct and highly recyclable. In addition to the SMEs directly involved in the planning and execution of timber and steel construction, manufacturers of steel skeleton structures as well as timber panel and solid wood elements will also benefit.

Responsibility

Load-bearing behavior of shear studs in composite floor decks with high ribs under fire loads

- AiF-FOSTA-Project: IGF-Nummer 21403 N

- Timeline: 2021-2023

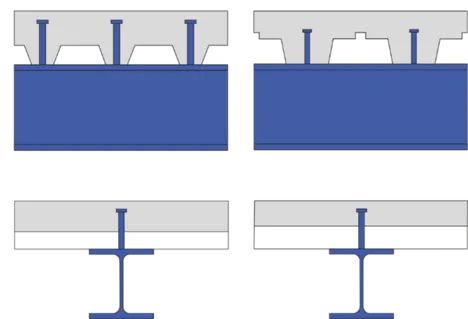

Composite slabs, consisting of steel composite profiled sheets and concrete, have been used successfully in composite construction for many years. In many cases, their cost-effectiveness depends on the span widths that can be achieved with the profiled sheets in the construction state. In order to increase the span widths, profiled sheets with high ribs are becoming used more frequently, which can minimize the number of secondary beams required and significantly increase the cost-effectiveness of the construction method.

The use of ever higher profiled sheet heights changes the load-bearing behavior of the shear connectors required to create the connection between the composite deck and the beam to greater flexibility and ductility, but also to a lower load-bearing capacity. In contrast to the application of profiled slabs in cold conditions, hardly any research results are available for fire conditions. Therefore, it is currently not possible to make any well-founded statement on the applicability of the design formula for the load-bearing capacity of head bolt anchors in case of fire according to DIN EN 1994-1-2 for high-rising profiled anchors.

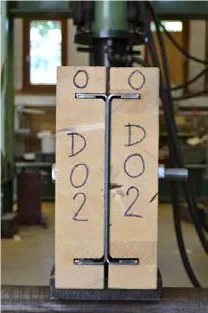

Building on the already completed research project "Minimum anchoring of composite girders in the event of fire", the applicability of partial composite anchoring in the event of fire is also to be examined in greater detail. It is to be examined whether the approaches developed for composite girders with solid concrete slabs can also be transferred to composite girders with high-rising profiled sheets.The implementation of the research objectives is to be achieved by an extensive experimental test program. While the local load-bearing behavior of the shear studs in the profiled sheet beads is to be investigated by means of push-out tests in accordance with DIN EN 1994-1-1 under fire load, the overall load-bearing behavior is to be analyzed by means of large-scale fire tests on composite girders. In addition to the test program, parameter studies on composite girders and push-out test specimens are planned using the Abaqus FE software.

Responsibility

Fire resistance of hot-dip galvanized composite beams made of high and high-strength structural steels

- AiF-FOSTA research project (GAV, FOSTA, DASt), IGF project no.: 21536 N

- Project period: 01/2021 - 06/2023

- Project partners: TUBS (iBMB) and RWTH Aachen

Current research shows that hot-dip galvanizing can significantly improve the fire resistance of steel. The DIN EN 1994-1-2 standard, which applies for hot dimensioning, is currently being revised to take into account the positive effects of hot-dip galvanizing in the case of a fire.

As a result, steel structures, in combination with moderate oversizing, can achieve the required fire resistance class of R30 without the need for additional passive fire protection measures. In the case of composite beams, the fire resistance R30 can be achieved with significantly increased material efficiency and economy by using higher-strength steels (e.g. S460 M / ML for hot-rolled profiles or for steels with a yield point of 690 N / mm2 for welded profiles).

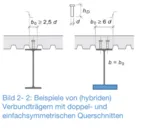

By forming single symmetrical, hybrid welded beams, such as a halved rolled section made of S460M with an optimized (Am / V ratio) lower flange made of S690Q and in combination with hot-dip galvanizing, a fire resistance of R30 should be ensured in an economical way.

The aim of the research project is therefore the development and verification of easily applicable rules for determining the fire resistance of hot-dip galvanized composite beams made of high-strength structural steels in the case of fire.

In the project, are considered various issues that are relevant to construction practice, but not yet researched or only insufficiently researched. This includes scientific questions about the development of the temperature profile over the height of the steel profile of a hot-dip galvanized composite beam, the material behaviour of high-strength steels at high temperatures, the heating behaviour of connections of hot-dip galvanized components (also in combination with protected components), the subject of possible liquid metal embrittlement of high-strength steels in the case of fire , the required minimum degree of shear connections in the case of fire for hot-dip galvanized composite girders and the optimized design of single-symmetrical, hybrid composite girder cross-sections.

Thus, a significant cost reduction of the shell construction costs by approx. 15% - 25% should be achieved, through a clever combination of several measures to optimize the fire protection, for example, by taking into account the lower emissivity of hot-dip galvanized steel components or by optimizing the minimum degree of shear connections in composite structures.

Responsibility