Nitrous oxide (N2O) can be emitted during the biological nitrogen removal as an undesired intermediate or side-product. With a greenhouse gas potential 298 times higher than that of carbon dioxide, its resistance time of 114 years in the atmosphere and its potential of ozone depletion, these emissions should be reduced as much as possible to mitigate their negative influence on the environment. However, nitrous oxide can also be used as an energy source. That is why this project does not only investigate the diverse biological N2O production pathways including reduction strategies during nitrogen removal processes, but also examines the intended production of nitrous oxide with coupled extraction processes for a beneficial recovery of nitrogen.

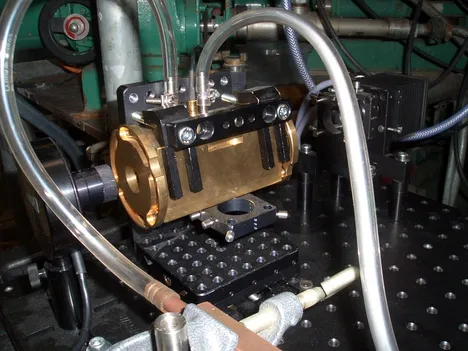

For both approaches, an experimental setup building upon reactor design experiences at Eawag (Switzerland) has been established. These set-ups consist of six fully automated reactors with a volume of 13 L each. The plant is controlled by the software CitectSCADA, which is not only responsible for the automation, but also acquires and logs all online measurements for oxygen, ammonium, nitrate, redox potential, conductivity, pH, water level and temperature for a desired timeframe. For the online measurement of N2O, an innovative laser-based photoacoustic cell with high temporal resolution developed by the Chair of Analytical Chemistry (TUM) is applied.

In order to derive reduction strategies for nitrous oxide, several single stage deammonification reactors with suspended sludge as well as with carrier with fixed biofilm are investigated. For the targeted production of nitrous oxide, the so-called CANDO process is studied and optimized.