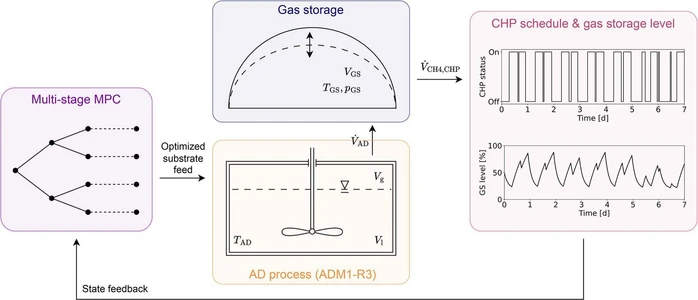

Revenues of anaerobic digestion (AD) plants can be increased by generating biogas and electricity on demand or through biogas upgrading. However, suitable control procedures for individual applications are required to guarantee optimal process conditions. Moreover, substrate characterization at full scale plants is often subject to large uncertainties. In this contribution, a multi-stage nonlinear model predictive controller (NMPC) was designed to optimize substrate feedings under uncertain substrate characterization. Simulations demonstrate that multi-stage NMPC provides biogas on demand to flexibly operate a combined heat and power unit, while safe gas storage filling limits are ensured (20 % safety margin) despite uncertain influent concentrations. Additionally, multi-stage NMPC successfully tracked changing setpoints of constant methane production for biogas upgrading within 12 h, and rejected disturbances posed by disturbing feedings of very high uncertainty. This study demonstrates that model-based control strategies like multi-stage NMPC can enhance the potential of anaerobic digestion plants by enabling demand-oriented operation despite substrate uncertainties and without fundamentally changing the existing hardware, which showcases more sustainable and profitable biogas production.